In todays fast-paced innovation landscape, the allure of rapid prototyping couldnt be stronger. Businesses from startups to industry giants are racing to bring their ideas to life quicker than ever, driven by the promise of efficiency and streamlined design processes.

However, the excitement often belies a complex web of costs that can dramatically impact the bottom line. While the initial investment in prototyping tools and technologies may seem manageable, hidden expenses lurk beneath the surface — from material sourcing and labor to the often-overlooked implications of iterative failures and longer development cycles.

As we delve into the true cost of rapid prototyping, it becomes imperative to unravel these multifaceted factors, highlighting how they can influence financial outcomes and ultimately determine a project’s success or failure. Understanding this intricate balance is essential for any organization aiming to thrive in an increasingly competitive market.

Understanding Rapid Prototyping: An Overview

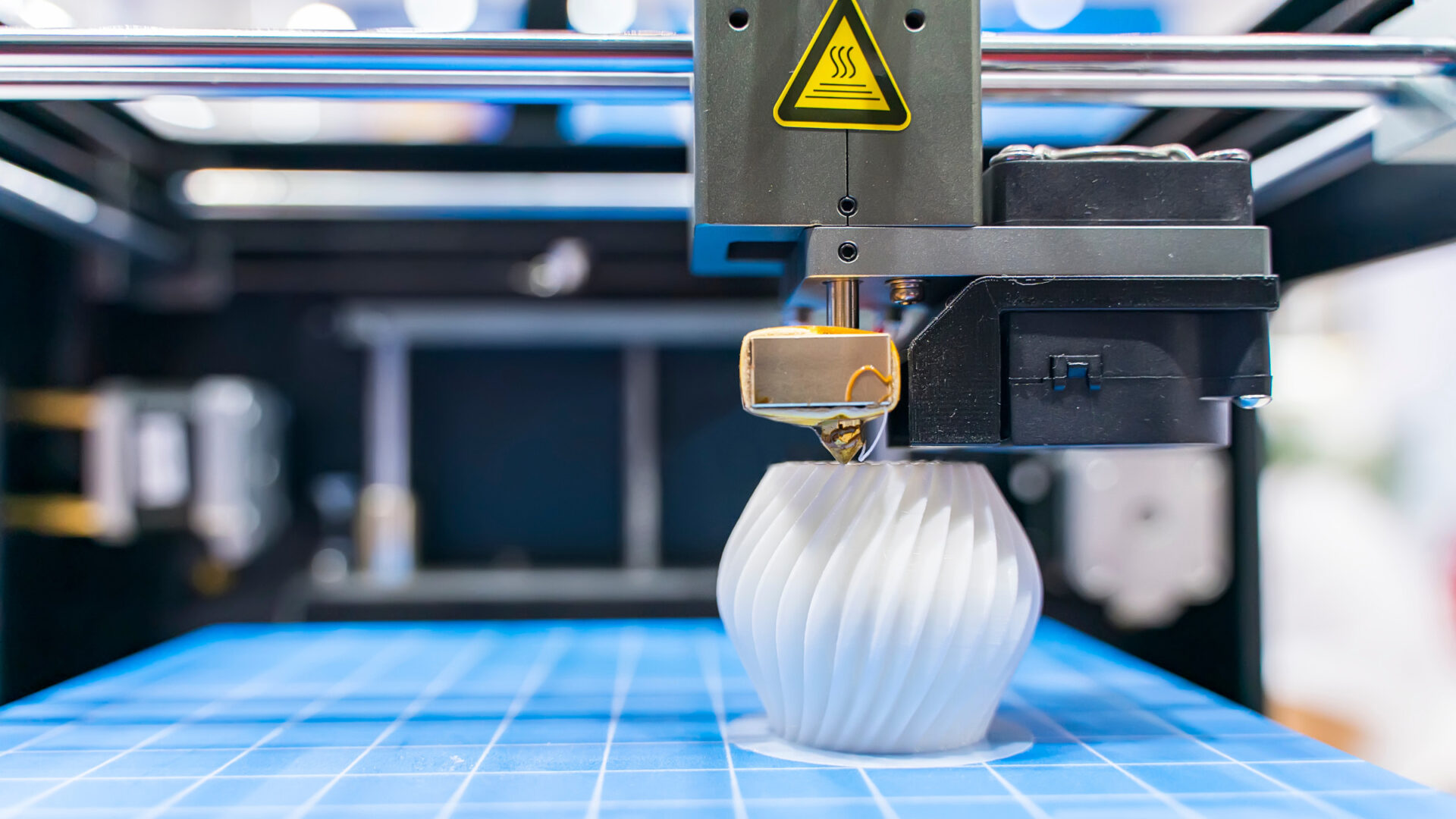

Rapid prototyping is a transformative approach that accelerates the design process, allowing ideas to transition swiftly from conception to tangible reality. By utilizing advanced technologies such as 3D printing and computer-aided design, teams can create, test, and iterate prototypes in a fraction of the time it traditionally takes.

This rapid cycle of feedback not only fosters innovation but also mitigates risks associated with product development. Prototyping services are instrumental in this process, offering specialized support to navigate the complexities of material selection, technology, and design expertise.

These services help streamline the creation and evaluation of prototypes, ensuring that each iteration is optimized for both performance and cost-effectiveness. However, it\’s essential to recognize that while rapid prototyping can significantly speed up timelines, it carries its own set of hidden costs and challenges.

Understanding the delicate balance between speed and cost-effectiveness is vital for any organization aiming to harness the full potential of rapid prototyping.

Quality Control: Ensuring Design Integrity

Quality control is the bedrock of effective rapid prototyping, serving as a critical safeguard against design flaws that could derail your projects success. As the pace of production accelerates, ensuring design integrity becomes increasingly challenging yet vital.

This involves a meticulous examination of prototypes at various stages, from the initial concept to the final model. By implementing rigorous testing protocols and leveraging advanced inspection technologies, teams can identify discrepancies early in the process, thereby avoiding costly reworks that can inflate budgets.

However, quality control is not merely a cost; it represents an investment in reliability and performance, essential for aligning with client expectations and market demands. Ultimately, a commitment to quality can differentiate a successful prototype from one that falls short, establishing a foundation for long-term growth and credibility in a competitive landscape.

Risk Management: Potential Financial Pitfalls

In the whirlwind of rapid prototyping, businesses often overlook lurking financial pitfalls that can demolish their budget. The desire for speed—while driving innovation—can lead to hasty decisions, such as underestimating material costs or misjudging the required quality of outputs.

Imagine investing time and resources into developing a sleek prototype only to discover that its functionality is compromised, necessitating costly revisions or complete overhauls. Moreover, the allure of cutting-edge technologies might entice companies to make impulsive investments in software or machinery, which can quickly spiral into unmanageable expenses.

The temptation to push projects ahead without adequate testing can also result in costly delays when prototypes fail to meet regulatory standards or consumer expectations. Thus, effective risk management becomes not just a luxury but a crucial strategy to safeguard the financial health of an organization navigating the complexities of rapid prototyping.

Conclusion

In conclusion, while rapid prototyping offers immense benefits in accelerating product development and reducing time to market, it is essential for businesses to carefully consider the various factors that influence their overall costs. From material selection and technology choices to the level of complexity in design and the specific prototyping services utilized, each element plays a crucial role in shaping the financial impact on your bottom line.

By conducting thorough assessments and seeking to optimize each stage of the prototyping process, companies can ensure that they harness the advantages of rapid prototyping while maintaining a sustainable cost structure. Ultimately, a strategic approach to these factors will enable businesses to innovate more effectively without compromising their economic viability.