Lasers are an incredible technology that has revolutionized many industries. From laser cutters to laser welders, they have become a staple of modern production lines.

But how accurately do movies depict the use of laser welders? This article explores the different kinds of laser welding and how accurately they are portrayed in films and TV shows. We will take a look at some common misconceptions about this advanced technology, as well as its potential applications for a variety of tasks.

Finally, we’ll examine whether today’s entertainment media is portraying these tools correctly or not.

Accuracy of Movie Depictions of Laser Welders

The increasing prevalence of laser welders in popular entertainment media has provided viewers with a glimpse into the capabilities and potential applications of this advanced technology. However, due to the reliance on special effects for dramatic effects, many depictions may be inaccurate or exaggerated.

While movies have shown laser welders being used to cut through steel walls and other materials that are impossible to penetrate using any kind of welding tool, they also often demonstrate their use in projects requiring extreme precision such as joining thin wires together without damaging surrounding components. By understanding the different types and uses of laser welders available today, filmmakers can strive for more accurate representation when depicting them on the screen which not only helps educate audiences but also provides an opportunity to showcase this amazing technology’s full potential.

Varieties and Uses of Laser Welding Technology

Laser welding is an advanced technology that has a wide range of applications in many industries. From medical implants to aerospace components, laser welders are being used to create precise and reliable welds.

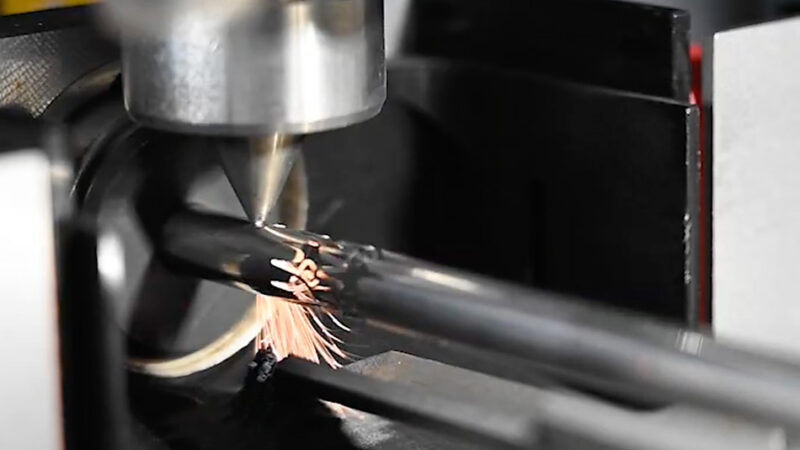

In the film industry, laser welding plays a significant role in the production of props and special effects, allowing filmmakers to achieve intricate details with minimum effort. There are different kinds of lasers used for welding: CO2 or carbon dioxide lasers; YAG (yttrium–aluminum–garnet) lasers; diode lasers; disk or direct diode lasers; fiber optic coupled lasers; excimer (xenon chloride) lasers.

Each type has its advantages and disadvantages depending on the task at hand. For example, CO2 laser welders produce high-power beams that can penetrate thicker materials but require higher maintenance costs than other types of laser welders.

On the other hand, diode laser welders provide low-cost solutions while still providing strong results, making them ideal for small projects and tight budgets. Laser welding is also being explored as a potential solution for 3D printing applications due to its accuracy and precision capabilities which could enable faster prototyping times compared to traditional manufacturing methods such as milling or CNC machining.

Advantages and Disadvantages of Different Types of Lasers

When exploring the different types of lasers available for welding purposes, it is important to consider both their advantages and disadvantages. YAG lasers offer a broad range of power levels that can be used in either continuous or pulsed modes, making them suitable for a wide variety of welding tasks.

However, they have long set-up times and require frequent maintenance to keep them running efficiently. CO2 lasers are the most commonly used type in both industrial and consumer settings due to their affordability and ease of use; on the other hand, their beam quality is relatively low compared with other laser types making them less precise than YAG or fiber lasers.

Fiber lasers produce high-quality beams that can cut through thicker materials but they are expensive and require more complex optics than other laser systems. When deciding which type will best suit your needs, it is essential to weigh up these pros and cons carefully before investing in any kind of technology.

How Laser Welders Can Change the World

The use of laser welders in movies has generally been accurate, but there is still a need for more research into the different types of lasers used and how they are depicted. Laser welding machines offer many advantages over other methods of welding and have proven to be reliable in many applications.

With further study on the different kinds of lasers available and their capabilities, Hollywood could potentially create an even more realistic view of laser welding technology.