Laser machines are widely used for precise material cutting and engraving, offering a range of benefits that other methods simply cannot match. The high-powered laser beam can easily penetrate through even the toughest materials with incredible accuracy, making it an invaluable tool in industrial settings.

This article will explore how laser machines work and why they have become so important in modern manufacturing processes. We will look at their many features such as speed, precision, versatility, and scalability to see why laser technology has revolutionized the way we cut and engrave materials today.

Finally, we will discuss some potential applications that could arise from this powerful technology in the future.

Introduction to Laser Cutting and Engraving

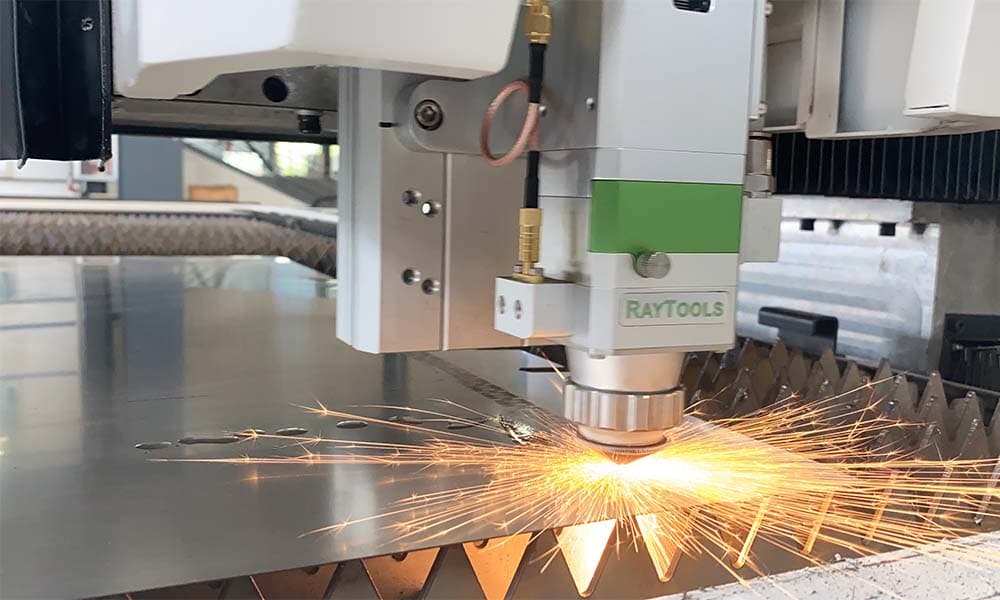

Laser technology has revolutionized the way materials are cut and engraved. By focusing a beam of light at incredibly high temperatures, laser machines can make precise cuts in metal, wood, plastic, glass, and other materials with minimal distortion or waste.

In addition to its precision cutting capabilities, laser engraving is also highly sought after for its ability to create detailed marks on even the most delicate surfaces without causing any damage. This article will provide an introduction to the various types of laser machines available today and discuss their uses in material cutting and engraving. Well, look at how lasers work alongside traditional tools like milling machines, saws, and routers as well as explore some of the unique advantages that come along with using this advanced technology.

Finally will take a closer look at some of the common applications for which laser-cutting is best suited including jewelry making, prototyping projects, and signage production.

Advantages of Using Laser Machines for Precise Material Cutting and Engraving

Laser machines are becoming increasingly popular in precise material cutting and engraving due to their many advantages. One of the main benefits is that they allow for extremely accurate cuts and engravings, which would be difficult or impossible to achieve using conventional machining methods.

Laser machines also have a high degree of repeatability as they can quickly cut multiple items with the same precision over and over again. Moreover, laser machines produce clean edges without any burrs or distortion, making them ideal for intricate designs such as logos or artwork.

Additionally, laser cutting produces minimal heat-affected zones around the cut line which reduces thermal stress on the material being cut. Furthermore, since no direct contact is made between tooling and workpiece during cutting there is less wear and tear on parts meaning fewer replacement costs in the long run.

All these features make laser machines an invaluable asset when it comes to precise material cutting and engraving applications.

The Different Types of Laser Cutters and Engravers

When it comes to precise material cutting and engraving, laser machines are often the preferred choice. They can be used for a variety of tasks from etching intricate patterns onto wood or metal to cutting through thick sheets of steel with relative ease.

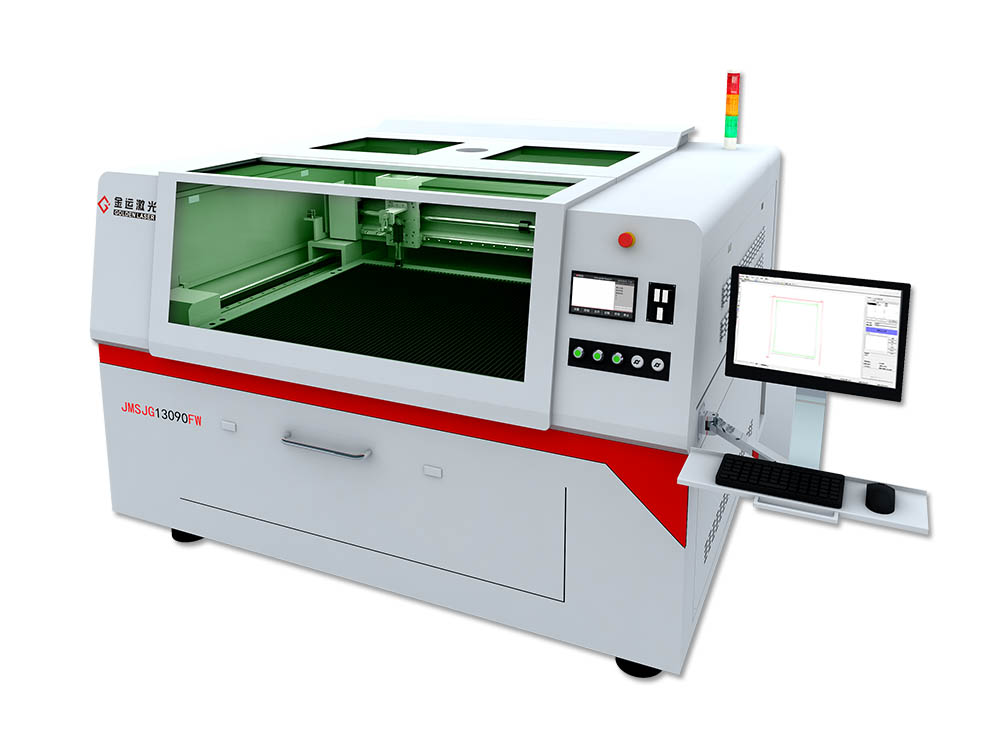

But what sets laser cutters apart from other machines is the wide range of options available in terms of models, power, accuracy, materials that they can work on, and more. Generally speaking, there are three main types of lasers used in these machines: CO2 lasers, Nd: YAG (Neodymium-doped yttrium aluminum garnet) lasers, and Fiber lasers.

Each type has its unique characteristics which make them suitable for different applications. For instance, CO2 lasers are best suited for soft materials such as acrylics while Nd: YAG is better at cutting harder metals like aluminum or stainless steel.

On the other hand, Fiber Lasers offer superior performance when compared to both CO2 and YAG but require greater initial investment due to their complexity and precision components needed for operation. Apart from this basic categorization, various specialized laser cutters come with additional features such as high-speed rotary axes for 3D engravings or special optics allowing them to work on curved surfaces without losing focus or accuracy along the edges.

Conclusion

In conclusion, laser machines have revolutionized the world of precise material cutting and engraving. Whether used by hobbyists or professionals, these powerful tools can easily cut through a variety of materials with ease and accuracy.

Laser machines are cost-effective, safe to use, and very versatile in virtually any industry requiring precision work. With so many advantages to offer,it’ss no wonder why they’ve become so popular over the years.

If you’re looking for an efficient way to create intricate designs on metal or other materials, then a laser machine is worth considering. To learn more about how laser machines can help you get the job done right, contact us today!